ELECTRIFICATION

Our thermal management solutions are tailored to improve the efficiency of heavy-duty equipment and vehicles, especially those transitioning to electrification.

As the foremost authority in engine cooling and thermal management control for diesel engine equipment, Horton, Inc. has long been trusted by the world’s leading trucking, construction, mining, and agriculture OEM manufacturers. Now, with the paradigm shift towards zero-emission vehicles (ZEV), these manufacturers continue to turn to Horton for our unparalleled expertise in cooling systems. Our proven track record and deep understanding of the complexities in heavy-duty vehicle operations uniquely position us to provide tailored solutions for ZEV equipment. OEMs seeking to navigate the transition towards electrification can rely on Horton’s knowledge and experience to ensure efficient and effective cooling systems that meet the rigorous demands of modern transportation.

Why Manufacturers Trust Horton

with ZEV Cooling Systems?

Enhanced Design Evaluation

We offer a team of experience design engineers specializing in electric and zero-emissions heavy-duty OEM vehicles and equipment. We conduct thorough assessments of customer needs and provide interactive design analysis, ensuring tailored solutions for sustainable transportation. With their expertise, Horton’s engineers optimize cooling systems to meet the evolving demands of the industry.

Flexible Technology Solutions

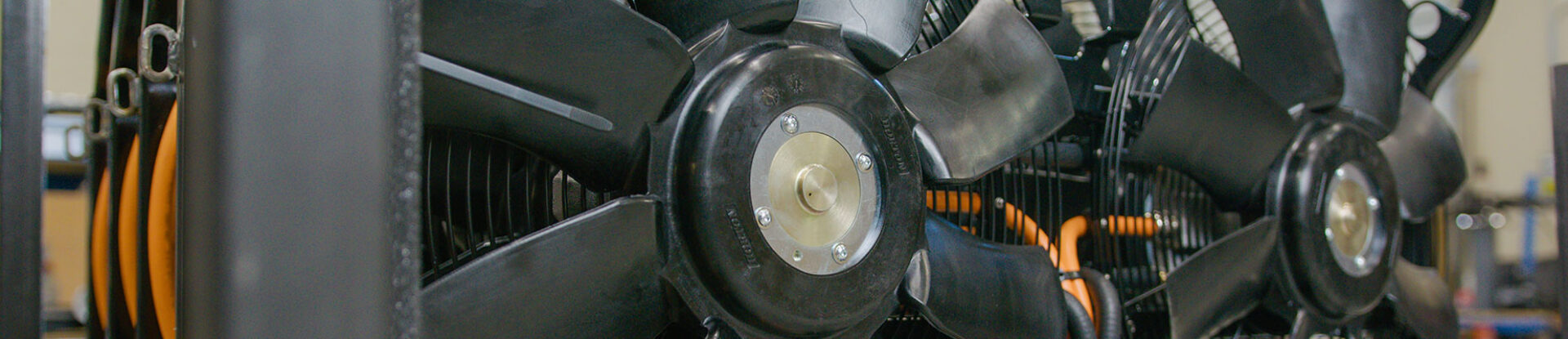

Horton, Inc. offers a range of flexible technology solutions, including a full-scale dynamometer lab and fan pressure wind tunnel. These resources enable comprehensive testing for both new and existing applications of heavy-duty OEM manufacturers‘ electric or zero-emissions vehicles and equipment. With state-of-the-art facilities, Horton ensures that customer needs are met with precision and efficiency.

Accelerated Prototyping

Horton, Inc. offers accelerated prototyping services to customers, facilitating swift development of heavy-duty OEM manufacturers‘ electric and zero-emissions vehicles and equipment. Our team collaborates closely with clients throughout the testing process, ensuring that quality and regulatory standards are met or exceeded. With Horton’s expertise, manufacturers can expedite innovation while maintaining industry-leading standards.

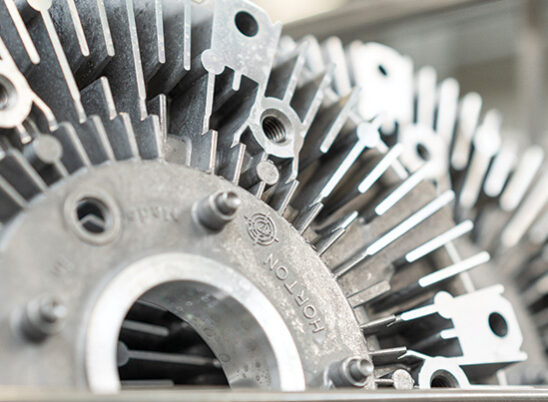

THERMAL EVOLUTION

Horton, Inc. is a leading provider of engine cooling solutions for diesel engines and heavy-duty vehicles. We have a long history of innovation and evolution in the industry. In response to the increasing demand for zero-emission vehicles, we now offer cutting-edge products for OEM manufacturers creating hydrogen, fuel cell, and electric vehicles. With over 60 years of experience, Horton is at the forefront of sustainable transportation, driving innovation in cleaner and more efficient mobility solutions globally.

How Do High Voltage, Hydrogen & Bev Cooling Systems Work?

High voltage engine cooling systems for heavy-duty battery electric vehicles (BEVs) and hydrogen fuel cell vehicles and equipment operate on a principle of efficiently managing thermal loads generated during operation. These systems typically incorporate advanced components such as high-capacity radiators, coolant pumps, and heat exchangers. In BEVs, the cooling system helps regulate temperatures of the high-voltage battery pack, ensuring optimal performance and longevity. For hydrogen fuel cell vehicles, the cooling system maintains ideal operating temperatures for the fuel cell stack, maximizing efficiency and reliability. Through a combination of active cooling strategies and sophisticated thermal management algorithms, these systems effectively dissipate heat generated by the vehicle’s powertrain components, ensuring smooth operation and extending the lifespan of critical components.

High-Voltage Cooling Systems for Heavy Duty Trucks

High-Voltage Cooling Systems for Off-Highway Equipment

Tell us about Your Project

Customized To Your NEEDS

We specialize in providing engine cooling systems, parts, and components tailored for OEM manufacturers producing heavy-duty vehicles and equipment for both on-highway and off-highway markets. With a commitment to excellence, we customize solutions to precisely meet the unique needs and specifications of each customer. Whether it’s optimizing cooling efficiency, enhancing durability, or meeting specific performance requirements, our service offerings ensure that OEM manufacturers receive reliable and high-quality cooling solutions designed to exceed expectations.

TAILORED ENGINEERING

We specialize in custom engine cooling solutions for OEM manufacturers in the heavy-duty vehicles and equipment sector. Our team of experienced Application Engineers works closely with customers to develop tailored thermal control systems. Our expertise spans industries such as construction, agriculture, mining, and trucking, ensuring optimal performance, durability, safety and efficiency for your applications. With a focus on innovation and collaboration, we deliver solutions that exceed industry standards and drive customer success.

Electrification FAQS

ZEV

How do cooling systems benefit heavy-duty electric equipment and zero-emission vehicles?

Cooling systems benefit heavy-duty electric equipment and zero-emission vehicles by helping to regulate the temperature of the components, ensuring that they operate efficiently and prevent overheating. Since heavy-duty electric equipment and zero-emission vehicles rely on batteries and electric motors for power, these systems can generate a significant amount of heat during operation. Cooling systems help dissipate this heat, prolonging the lifespan of the components and improving overall performance. Without an effective cooling system, these vehicles and equipment would be more prone to breakdowns and reduced efficiency, ultimately hindering their ability to operate effectively and sustainably.

What types of cooling systems are commonly used for heavy-duty electric equipment and ZEVs?

The types of cooling systems commonly used for heavy-duty electric equipment and zero-emission vehicles (ZEVs) include liquid cooling systems and air cooling systems. Liquid cooling systems use a coolant fluid to absorb heat from the equipment or vehicle’s components and then transfer it to a radiator where it is dissipated. This type of system is often used in high-performance electric vehicles or equipment that generate a lot of heat. Air cooling systems, on the other hand, use fans to blow air over the components to dissipate heat. This type of system is more common in lighter-duty electric vehicles and equipment where heat generation is lower. Both systems are essential for maintaining optimal performance and preventing overheating in heavy-duty electric equipment and ZEVs.

Are there any specific considerations when designing cooling systems for ZEVs compared to traditional vehicles?

When designing cooling systems for Zero Emission Vehicles (ZEVs) compared to traditional vehicles, there are several specific considerations that need to be taken into account. ZEVs typically have different powertrain configurations and battery systems than traditional vehicles, which can impact the heat generated and the thermal management requirements. In ZEVs, cooling systems need to be efficient in order to keep the batteries and electric components at optimal operating temperatures to ensure performance and longevity. Additionally, ZEVs rely heavily on electric power, so cooling systems need to be designed to minimize energy consumption and maximize efficiency. Overall, designing cooling systems for ZEVs requires a different approach and consideration of the unique characteristics of electric vehicles.

What advancements have been made in cooling system technology for heavy-duty electric equipment and ZEVs in recent years?

In recent years, advancements in cooling system technology for heavy-duty electric equipment and zero-emission vehicles (ZEVs) have focused on improving energy efficiency and extending the range of these vehicles. One area of advancement is the development of more efficient heat exchangers and thermal management systems that help regulate the temperature of electric components and batteries, thereby enhancing overall performance and longevity. In addition, manufacturers have been exploring the use of advanced materials and designs for cooling systems to reduce weight and minimize energy consumption. These advancements play a crucial role in addressing one of the key challenges of heavy-duty electric equipment and ZEVs, which is maintaining optimal performance and range under various operating conditions.

Fuel Cell

How does the engine cooling system work in fuel cell heavy-duty vehicles and equipment?

What are common issues that can arise in engine cooling systems for fuel cell vehicles?

Common issues in engine cooling systems for fuel cell vehicles may include coolant leaks, pump malfunctions, air pockets in the coolant system, and overheating due to inadequate cooling capacity. Regular maintenance and monitoring are essential to detect and address these issues promptly, ensuring the reliable performance of the vehicle’s cooling system.

How often should engine cooling systems be inspected and maintained in fuel cell heavy-duty vehicles?

Engine cooling systems in fuel cell heavy-duty vehicles should be inspected and maintained according to the manufacturer’s recommendations, typically every 6 to 12 months or as specified in the vehicle’s maintenance schedule. Regular inspections help ensure optimal performance, detect potential issues early, and extend the lifespan of the cooling system components.

Are there specific types of coolant or additives recommended for use in engine cooling systems for fuel cell vehicles?

Yes, specific types of coolant or additives are recommended for use in engine cooling systems for fuel cell vehicles. It is crucial to use coolant that meets the manufacturer’s specifications to ensure compatibility with the fuel cell system and prevent corrosion or other detrimental effects. Consult the vehicle’s manual or contact Horton, Inc., for recommendations on the appropriate coolant and additives for your fuel cell vehicle.

What are some best practices for optimizing the performance of engine cooling systems in fuel cell heavy-duty vehicles and equipment?

Some best practices for optimizing the performance of engine cooling systems in fuel cell heavy-duty vehicles and equipment include regular maintenance checks, ensuring proper coolant levels and quality, monitoring for leaks or air pockets, and ensuring adequate airflow through radiators and heat exchangers. Additionally, following manufacturer guidelines for operating temperatures and load conditions can help maximize efficiency and lifespan of the cooling system components.