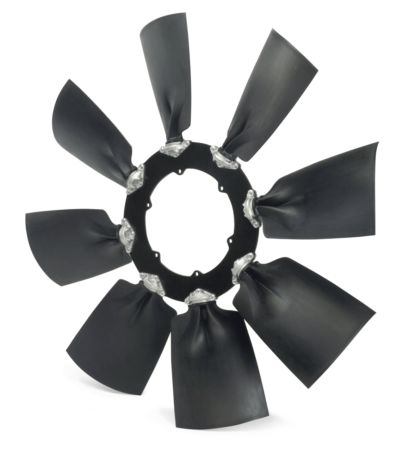

Fan Drives/Clutches

Horton is the world’s largest producer of fans for the on- and off-highway markets. Accordingly, it has an edge in terms of design and experience with cutting-edge materials beca…

Explore a wide range of cooling solutions for various markets, including fan drives, fan clutches, electric applications cooling options, and more. Find the perfect customized solution for your OEM and after-market needs.

Horton is the world’s largest producer of fans for the on- and off-highway markets. Accordingly, it has an edge in terms of design and experience with cutting-edge materials beca…

Horton is the world’s largest producer of fans for the on- and off-highway markets. Accordingly, it has an edge in terms of design and experience with cutting-edge materials beca…

Products Markets

Products Markets

Products Markets

Products Markets

Products Markets

Products Markets

Products Markets

Products Markets

Products Markets

Products Markets