products & MARKET

Off-highway

For more than 65 years, Horton has been enhancing noise reduction, fuel efficiency, and long-term durability in off-highway equipment with our superior fans, fan drives, and clutches. When it comes to tailored solutions for your specific requirements in the off-highway sector, Horton stands unrivaled.

Maximizing Fuel Control

Horton offers assistance in selecting the appropriate cooling system for your vehicles based on their operating conditions and environments. They can help optimize the fan cycling frequency and speed for maximum efficiency.

Reducing Noise

Horton fan drives and fans help keep your engine cool and reduce noise levels. This is beneficial for the environment and improves the comfort of vehicle operators, leading to increased productivity.

INCREASING RELIABILITY

Horton designs cooling systems for diverse environments, ensuring optimal performance. Our products exceed OEM standards and meet stringent industry certifications like ISO 9001, ISO 14001, and ISO/TS 16949, guaranteeing lasting quality and reliability.

OFF-HIGHWAY FAN DRIVES

Discover Horton, Inc.’s specialized fan clutch solutions designed for heavy-duty engine cooling systems in the off-highway market. Improve the efficiency and reliability of your vehicles and equipment with our top-notch cooling solutions.

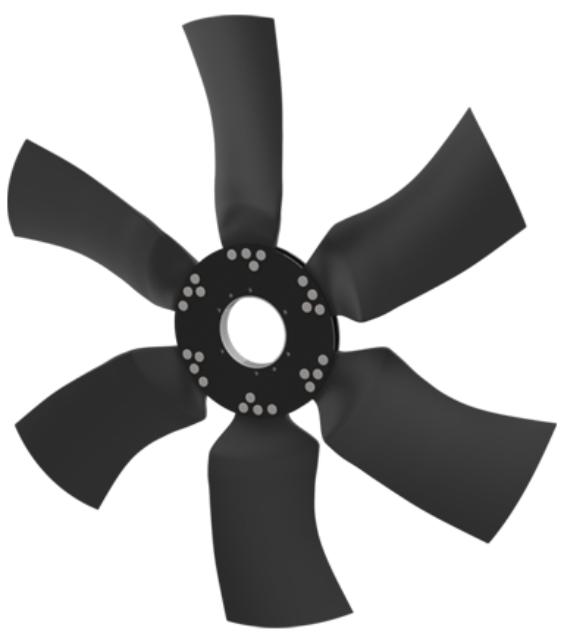

OFF-HIGHWAY FANS

Enhance your heavy-duty engine cooling system with Horton, Inc.’s top-of-the-line heavy duty fans. Increase the effectiveness and longevity of your commercial vehicles and equipment. Explore our various fan material options from metal, nylon composite to our proprietary HTEC material fan solutions engineered to maximize cooling efficiency, even under intense work conditions.

LET US HELP WITH YOUR PROJECT

CUSTOMIZED SOLUTIONS

Our company focuses on providing tailored engine cooling solutions for off-highway heavy-duty equipment and vehicles, including diesel engines and zero-emission platforms such as BEVs, fuel cells, and hydrogen engines. Through our commitment to customizing solutions for each OEM partner, we offer top-notch engineering expertise and support to enhance thermal management and empower our customers within the off-highway sector.

FREQUENTLY ASKED QUESTIONS

General

How do engine cooling systems work in off-highway heavy-duty vehicles and equipment?

The engine cooling system in off-highway heavy-duty vehicles and equipment plays a critical role in regulating engine temperature. Coolant is circulated through the engine, absorbing heat from the combustion process, before being transferred to the radiator for dissipation. Additional cooling mechanisms like fans or liquid-to-air coolers may be utilized to further reduce coolant temperature. This process is essential for preventing engine overheating and maintaining peak performance and durability of the vehicle or equipment.

What are the consequences of a malfunctioning engine cooling system in off-highway vehicles and equipment like construction equipment, agriculture and mining?

The engine cooling system in off-highway vehicles and equipment, such as construction equipment, agriculture, and mining machinery, is crucial for preventing engine overheating and potential catastrophic damage. Without proper cooling, these vehicles can experience costly repairs, downtime, and decreased productivity. Additionally, engine overheating poses safety risks to operators and those nearby. It is important to regularly maintain and monitor the engine cooling system to prevent these consequences and maintain smooth operation of off-highway equipment.

Are there any advancements in engine cooling systems for on-highway heavy-duty vehicles and equipment in recent years?

Recent advancements in engine cooling systems for off-highway heavy-duty vehicles and equipment have revolutionized the industry. Innovations such as the use of more efficient and durable materials in radiator construction, advanced electronic control systems for monitoring engine temperature, and the integration of variable speed cooling fans and thermostats have significantly improved heat dissipation, cooling capacity, engine performance, efficiency, and emissions. These developments have not only increased engine reliability and lifespan but have also played a key role in enhancing fuel efficiency and reducing environmental impact.

OEM

What factors should OEM commercial manufacturers consider when designing off-highway engine cooling systems?

Designing off-highway engine cooling systems for OEM commercial manufacturers involves considering various factors. These include the specific operating conditions and environment of the engine, which greatly influence the cooling system requirements. The size and power of the engine are crucial considerations, as larger engines produce more heat and demand a more robust cooling system. Moreover, the vehicle type and intended applications play a significant role in determining the cooling system design. Evaluating factors like airflow, cooling capacity, and space limitations is essential for achieving optimal performance and efficiency in off-highway engine cooling systems.

1. Engine size and power output: The cooling system needs to be appropriately sized and designed to handle the heat generated by the engine’s size and power output.

2. Operating conditions: Consider the range of operating conditions the vehicle will encounter, such as temperature extremes, high altitudes, and heavy loads, as these can impact cooling system performance.

3. Cooling system components: Selecting high-quality components, such as radiators, fans, and coolant, is crucial to ensure the system functions properly and has a long lifespan.

4. Airflow design: Proper airflow design is essential to ensure efficient heat dissipation. This includes the placement of radiators, fans, and air ducts to optimize cooling.

5. Maintenance requirements: Designing a cooling system that is easy to access and maintain can help prolong its lifespan and prevent issues related to overheating.

6. Environmental considerations: Consider the impact of the cooling system on the environment, such as emissions and energy efficiency, and strive to design a system that minimizes negative environmental effects.

By taking these factors into account during the design process, OEM commercial manufacturers can create on-highway engine cooling systems that are reliable, efficient, and meet the specific requirements of the vehicle and its operating conditions.

How do on-highway engine cooling systems differ from off-highway engine cooling systems?

The differences between on-highway and off-highway engine cooling systems are significant. On-highway engines, which operate at high speeds and heavy loads, necessitate more efficient cooling systems that are larger and more complex to manage increased heat production. In contrast, off-highway engines, found in construction or agricultural machinery, require more robust cooling systems to withstand harsh working conditions, dust, and debris. These systems are designed to be durable and resistant to damage, sometimes incorporating protective features like screens or guards to safeguard against external factors.

What are the common challenges faced by OEM commercial manufacturers in designing efficient engine cooling systems for off-highway vehicles?

OEM commercial manufacturers encounter numerous challenges when developing engine cooling systems for off-highway vehicles. One common obstacle is finding the right balance between cooling efficiency and space limitations within the vehicle’s design. Off-highway vehicles typically have restricted space for cooling components, making it difficult to create a system that effectively dissipates heat without encroaching on available room. Moreover, these vehicles often operate in rugged, dusty environments, leading to potential issues such as clogging and decreased cooling system effectiveness. Manufacturers must also account for the diverse operating conditions of off-highway vehicles, ranging from heavy-duty workloads to idle periods, and devise a cooling system that can regulate engine temperature effectively in all scenarios. Additionally, factors like cost constraints and adherence to emissions standards further complicate the intricate process of designing efficient engine cooling systems.

What advancements have been made in on-highway engine cooling technology in recent years?

Recent advancements in off-highway engine cooling technology have been focused on enhancing efficiency and reducing emissions. Key developments include the utilization of variable speed fan drives, which adjust fan speed based on engine temperature to optimize cooling while minimizing power consumption. Additionally, the integration of advanced materials like aluminum and composites in radiator construction has resulted in reduced weight and improved heat transfer capabilities. Furthermore, the incorporation of electronic control systems and sensors enables real-time monitoring of engine temperatures and cooling system performance, facilitating proactive maintenance and troubleshooting. These advancements collectively work towards improving the reliability and performance of off-highway engines while simultaneously decreasing their environmental impact.

How important is proper maintenance and servicing of off-highway engine cooling systems for the overall performance and longevity of commercial vehicles?

Proper maintenance and servicing of off-highway engine cooling systems are extremely important for the overall performance and longevity of commercial vehicles. The cooling system plays a crucial role in preventing overheating and ensuring that the engine functions properly. If the cooling system is not properly maintained, it can lead to issues such as reduced engine efficiency, increased fuel consumption, and even engine damage. Regular servicing and maintenance of the cooling system can help prevent these problems and ensure that the vehicle operates at its optimal level. Neglecting maintenance can result in costly repairs and possibly even the need for a complete engine replacement, which can significantly impact the longevity and performance of the commercial vehicle. Therefore, prioritizing proper maintenance of off-highway engine cooling systems is essential for the overall health and efficiency of commercial vehicles.

Failure to properly maintain the engine cooling system can result in overheating, which can lead to engine damage and potentially costly repairs. In extreme cases, a malfunctioning cooling system can even cause the engine to fail completely. By maintaining the cooling system, commercial vehicle owners can prolong the life of their engines, improve fuel efficiency, and avoid costly downtime for repairs. This ultimately helps to ensure the overall performance and longevity of the commercial vehicle.

Customized

What are some customized solutions for engine cooling systems in zero-emission vehicles?

Although the knowledge of manufacturing, maintenance, and engine cooling systems in zero-emission vehicles (ZEV) is still growing, there are everal innovative approaches are being explored to address this need:

- Active Thermal Management: Utilizing advanced algorithms and sensors, active thermal management systems can dynamically adjust coolant flow and fan speed based on real-time temperature data. This ensures precise cooling tailored to the vehicle’s operating conditions, maximizing efficiency and battery life.

- Liquid Cooling Systems: In contrast to traditional air-cooled systems, liquid cooling solutions can efficiently dissipate heat from critical components such as electric motors, power electronics, and battery packs. Custom-designed coolant circuits with optimized flow paths can enhance heat transfer efficiency and minimize energy consumption.

- Integrated Heat Exchangers: Integrating heat exchangers into the vehicle’s chassis or body panels can provide additional cooling capacity without compromising aerodynamics or interior space. These innovative designs leverage the vehicle’s structure as a heat sink, enhancing thermal performance while reducing weight and complexity.

- Thermal Insulation and Management: Effective thermal insulation materials and techniques can minimize heat transfer from the powertrain to the passenger compartment, improving cabin comfort and reducing the load on the cooling system. Advanced insulation materials such as aerogels or vacuum-insulated panels offer excellent thermal resistance while being lightweight and compact.

- Variable Geometry Cooling Ducts: Employing adjustable cooling ducts or louvers allows for precise control over airflow distribution, optimizing cooling efficiency for different driving conditions. This adaptive approach ensures effective heat dissipation while minimizing aerodynamic drag and energy consumption.

- Regenerative Cooling Systems: Integrating regenerative cooling technology allows waste heat from the powertrain to be captured and recycled to supplement the cooling system. By harnessing this otherwise wasted energy, regenerative cooling systems can improve overall vehicle efficiency and reduce environmental impact.

- Predictive Maintenance Systems: Implementing predictive maintenance algorithms can proactively identify potential cooling system issues before they escalate, enabling timely intervention and preventing costly repairs or downtime. Real-time monitoring of coolant flow, temperature, and pressure parameters can help optimize system performance and reliability.

By integrating these customized solutions, zero-emission vehicles can achieve optimal thermal management, maximizing efficiency, performance, and reliability while minimizing environmental impact.

Are there any specific challenges in implementing customized solutions for engine cooling systems in zero-emission vehicles?

Implementing customized solutions for engine cooling systems in zero-emission vehicles faces several challenges:

- Efficiency Optimization: Ensuring cooling system efficiency while minimizing energy consumption is crucial for maximizing vehicle range.

- Component Integration: Integrating cooling components into the vehicle’s design without compromising other systems or aesthetics requires careful engineering.

- Thermal Management: Managing heat dissipation from electric powertrains and battery packs without affecting performance or safety is a complex task.

- Cost Considerations: Developing and implementing customized solutions can be expensive, necessitating cost-effective approaches without sacrificing performance.

- Regulatory Compliance: Meeting stringent environmental regulations and safety standards adds complexity to the design and implementation process.

Addressing these challenges requires collaboration between engineers, designers, and manufacturers to develop innovative solutions that balance efficiency, performance, and cost-effectiveness in zero-emission vehicles.

How do these customized solutions compare to traditional engine cooling systems in terms of performance and sustainability?