PRODUCTS & MARKETS

AFTERMARket

Discover a wide range of parts and solutions for heavy-duty vehicles and equipment from remanufactured fan clutches to repair kits for preventive maintenance.

Engine cooling solutions are crucial for heavy-duty equipment to maintain optimal performance. Horton, Inc. specializes in advanced thermal control systems to regulate engine temperature and prevent overheating. Our high-quality fan clutches and repair kits support preventative maintenance for on-road semi-trucks and off-highway vehicles. By using our durable products, fleets and truck owner-operators can reduce maintenance and cost risks while meeting customer demands efficiently.

Why Fleets and Independent Owner Operators Choose Horton?

QUALITY & RELIABILITY

For years, Horton has been a trusted supplier of aftermarket engine cooling system parts for fleets and owner-operators. Our fan clutches, fans, and components are renowned for their durability and quality, ensuring reliable performance. With extensive experience and top-notch engineering, we deliver long-lasting solutions preferred by those who prioritize excellence and dependability in heavy-duty vehicle operations.

COMMITMENT TO SERVICE

We are dedicated to training heavy-duty technicians and providing top-notch service to help you with vehicle and equipment issues. Whether it’s an emergency truck down situation, optimizing your equipment with superior engine cooling parts, or offering training on preventative maintenance, we ensure reliable and efficient solutions for you.

ON-TIME DELIVERy

Prioritizing delivered parts to our customers quickly and efficiently, is part of our cornerstone. Our inventory is always well-stocked, ensuring that you can order engine cooling system parts with confidence. You have the option to have the parts delivered promptly or pick them up from any of our numerous Quickship warehouses nationwide in the United States and Canada.

What Aftermarket Products Are Common for Heavy-Duty Applications?

In the realm of aftermarket solutions for OEM trucks and commercial vehicles, our lineup boasts the versatile HS Fan series, the innovative K32 Dual Pilot, and the efficient DMA Advantage Repair Kits. Tailored for both long-haul interstate journeys and local delivery services, these offerings cater to diverse needs. With customizable options available in the HS Fan series and the cost-effective cooling solutions of the K32 Dual Pilot series, we seamlessly integrate with KYSOR® parts for enhanced compatibility. Engineered to excel across various transport conditions and climates, our products guarantee consistent and optimal performance for all commercial truck applications.

FAN DRIVES

The K32 Dual Pilot fan clutch comes with world-class customer service and quality, so even fleets running competitors’ fan drives can experience the Horton advantage.

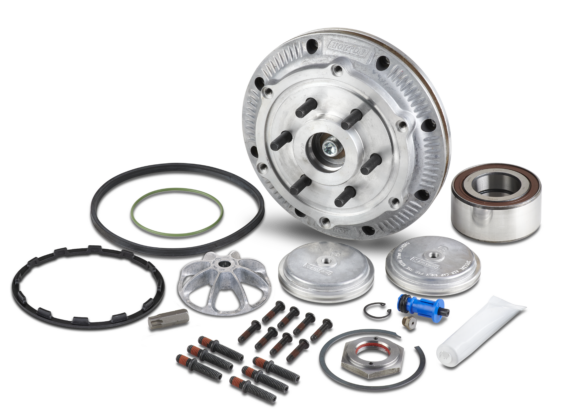

REPAIR KITS

Horton DM Advantage fan clutch repair kits streamline operations for parts managers and diesel technicians. With a limited number of part numbers to stock, managers can efficiently manage inventory while technicians swiftly repair trucks, minimizing downtime. Options like friction liner kits, seal kits, bearing kits, and more cater to diverse needs.

TEChnician Training

Horton, Inc. is a leader in heavy-duty vehicle maintenance, offering training programs designed for both fleets and owner operators. We specialize in engine cooling systems, covering topics such as fan drives, clutches, and repairs. Our curriculum is detailed and thorough, ensuring technicians are well-equipped to maintain heavy-duty engines for optimal performance and longevity. We are dedicated to empowering professionals in the field and providing expertise to the industry.

FREQUENTLY ASKED QUESTIONS

How do engine cooling systems work in on-highway heavy-duty vehicles and equipment?

Engine cooling systems in on-highway heavy-duty vehicles and equipment work by circulating coolant through the engine to absorb heat and then transferring that heat to the radiator for dissipation. The coolant absorbs heat from the engine block and cylinder head, preventing the engine from overheating. The heated coolant is then pumped to the radiator, where it releases the heat into the surrounding air through the radiator fins, cooling it down. The now cooled coolant is then circulated back to the engine to repeat the process. This cycle helps maintain the engine’s operating temperature within a safe range and prevents overheating, which can lead to engine damage. Additionally, cooling systems in heavy-duty vehicles often include features such as thermostats, water pumps, and cooling fans to regulate the temperature and ensure optimal cooling efficiency.

What are the consequences of a malfunctioning engine cooling system in these vehicles?

A malfunctioning engine cooling system in a vehicle can have serious consequences. If the engine overheats due to a cooling system failure, it can lead to major engine damage such as blown head gaskets, warped cylinder heads, or even a cracked engine block. This can result in costly repairs or even the need for a full engine replacement. In addition, overheating can cause a vehicle to break down unexpectedly, leaving the driver stranded and potentially causing a dangerous situation on the road. Regular maintenance and prompt attention to any cooling system issues are essential to prevent these consequences.

Are there any advancements in engine cooling systems for on-highway heavy-duty vehicles and equipment in recent years?

Yes, there have been advancements in engine cooling systems for on-highway heavy-duty vehicles and equipment in recent years. Some of the advancements include the use of more efficient and durable cooling components, such as high-performance radiators and cooling fans, as well as the development of electronic engine cooling systems that can automatically adjust cooling levels based on engine temperature and operating conditions. Additionally, there has been an increased focus on improving overall engine efficiency and reducing emissions, which has led to the development of more advanced engine cooling systems that can help optimize engine performance while also reducing fuel consumption and environmental impact.

What factors should OEM commercial manufacturers consider when designing on-highway engine cooling systems?

When designing on-highway engine cooling systems, OEM commercial manufacturers should consider several factors to ensure the system operates efficiently and effectively. Some key factors to consider include:

1. Engine size and power output: The cooling system needs to be appropriately sized and designed to handle the heat generated by the engine’s size and power output.

2. Operating conditions: Consider the range of operating conditions the vehicle will encounter, such as temperature extremes, high altitudes, and heavy loads, as these can impact cooling system performance.

3. Cooling system components: Selecting high-quality components, such as radiators, fans, and coolant, is crucial to ensure the system functions properly and has a long lifespan.

4. Airflow design: Proper airflow design is essential to ensure efficient heat dissipation. This includes the placement of radiators, fans, and air ducts to optimize cooling.

5. Maintenance requirements: Designing a cooling system that is easy to access and maintain can help prolong its lifespan and prevent issues related to overheating.

6. Environmental considerations: Consider the impact of the cooling system on the environment, such as emissions and energy efficiency, and strive to design a system that minimizes negative environmental effects.

By taking these factors into account during the design process, OEM commercial manufacturers can create on-highway engine cooling systems that are reliable, efficient, and meet the specific requirements of the vehicle and its operating conditions.

How do on-highway engine cooling systems differ from off-highway engine cooling systems?

On-highway engine cooling systems are typically designed to handle higher speeds and longer periods of continuous operation compared to off-highway engine cooling systems. They often have larger radiators and more powerful fans to help dissipate heat more efficiently. Off-highway engine cooling systems, on the other hand, are usually designed to operate in more challenging environments with dust, mud, and debris, so they may have additional features such as larger air filters and protective covers to prevent damage. Additionally, off-highway engines may have different cooling requirements based on their specific application, such as construction equipment or agricultural machinery.

What are the common challenges faced by OEM commercial manufacturers in designing efficient engine cooling systems for on-highway vehicles?

Some common challenges faced by OEM commercial manufacturers in designing efficient engine cooling systems for on-highway vehicles include:

1. Space constraints: On-highway vehicles have limited space for engine cooling systems, making it challenging to design systems that efficiently cool the engine without taking up too much space.

2. Compliance with emissions regulations: Commercial vehicles need to comply with strict emissions regulations, which can impact the design of engine cooling systems. Manufacturers need to ensure that the cooling system does not contribute to higher emissions.

3. High engine temperatures: On-highway vehicles often operate under high load conditions, leading to high engine temperatures. Designing a cooling system that can effectively cool the engine under these conditions is a challenge.

4. Varying environmental conditions: On-highway vehicles operate in varying environmental conditions, from extreme heat to cold weather. Designing a cooling system that can perform efficiently in all these conditions is a challenge.

5. Cost considerations: OEM commercial manufacturers need to balance the performance of the engine cooling system with cost considerations. Designing an efficient cooling system that is also cost-effective can be a challenge.

Overall, designing efficient engine cooling systems for on-highway vehicles involves overcoming these challenges to ensure optimal engine performance and longevity.

What advancements have been made in on-highway engine cooling technology in recent years?

In recent years, advancements in on-highway engine cooling technology have focused on increasing efficiency, reducing emissions, and improving overall performance. Some of the key advancements include:

1. Integrated cooling systems: Many modern engines have integrated cooling systems that allow for better control of coolant flow and temperature. This helps to optimize engine performance and reduce the risk of overheating.

2. Variable speed fans: Variable speed fans are designed to adjust their rotation speed based on engine temperature, helping to minimize energy consumption and improve overall cooling efficiency.

3. Electronic cooling controls: Electronic cooling controls allow for real-time monitoring of engine temperature and coolant flow, enabling more precise control over the cooling process and reducing the risk of overheating.

4. Improved cooling fluids: Advances in cooling fluid technology have led to the development of new formulations that offer better heat transfer properties and increased longevity, helping to maintain optimal engine temperature levels.

5. Aerodynamic design: Many modern vehicles are designed with improved aerodynamics to reduce air resistance and improve airflow over the engine, which can help to enhance cooling performance.

Overall, these advancements in on-highway engine cooling technology have resulted in more efficient, reliable, and environmentally friendly cooling systems for vehicles on the road today.

How important is proper maintenance and servicing of on-highway engine cooling systems for the overall performance and longevity of commercial vehicles?

Proper maintenance and servicing of on-highway engine cooling systems are crucial for the overall performance and longevity of commercial vehicles. The engine cooling system helps regulate the temperature of the engine, preventing it from overheating and causing damage. Regular maintenance, such as checking coolant levels, inspecting hoses and belts, and flushing the system, can help ensure that the cooling system is working effectively.

Failure to properly maintain the engine cooling system can result in overheating, which can lead to engine damage and potentially costly repairs. In extreme cases, a malfunctioning cooling system can even cause the engine to fail completely. By maintaining the cooling system, commercial vehicle owners can prolong the life of their engines, improve fuel efficiency, and avoid costly downtime for repairs. This ultimately helps to ensure the overall performance and longevity of the commercial vehicle.

What factors should fleet managers consider when choosing aftermarket engine cooling parts and components for their trucks?

When choosing aftermarket engine cooling parts and components for their trucks, fleet managers should consider several factors:

1. Compatibility with the specific make and model of the truck: It is important to ensure that the aftermarket parts and components are compatible with the truck’s engine and cooling system to ensure proper fit and function.

2. Quality and reliability: Choose reputable aftermarket brands or manufacturers that offer high-quality and reliable parts to ensure the longevity and performance of the cooling system.

3. Cost-effectiveness: Consider the cost of the aftermarket parts and components in comparison to OEM (original equipment manufacturer) parts. While aftermarket parts may be more affordable, it is important to balance cost with quality.

4. Warranty and customer support: Look for aftermarket parts and components that come with a warranty and reliable customer support in case any issues arise.

5. Performance and efficiency: Consider aftermarket parts that offer improved performance and efficiency over stock components, such as enhanced cooling capacity or better heat dissipation.

6. Installation and maintenance: Choose aftermarket parts that are easy to install and maintain, to minimize downtime and ensure smooth operation of the truck.

By considering these factors, fleet managers can make informed decisions when selecting aftermarket engine cooling parts and components for their trucks.

How can truck drivers ensure the proper maintenance and care of their engine cooling components to prevent breakdowns on the road?

Truck drivers can ensure the proper maintenance and care of their engine cooling components by following these guidelines:

1. Regularly check and replace coolant levels: Coolant is essential for regulating the temperature of the engine. It is important to regularly check coolant levels and top up or replace coolant as needed.

2. Inspect hoses and belts: Hoses and belts play a crucial role in the cooling system. Inspect these components regularly for signs of wear and tear, and replace them if necessary to prevent breakdowns.

3. Clean the radiator: The radiator is responsible for dissipating heat from the engine. Regularly clean the radiator to remove any debris or dirt that may restrict airflow and hinder cooling efficiency.

4. Check the thermostat: The thermostat regulates the flow of coolant through the engine. Ensure that the thermostat is working properly to prevent overheating and potential breakdowns.

5. Monitor engine temperature: Keep an eye on the engine temperature gauge while driving. If the temperature starts to rise abnormally, pull over and investigate the issue before it leads to a breakdown.

6. Schedule regular maintenance checks: In addition to regular inspections, schedule routine maintenance checks with a qualified mechanic to ensure that all cooling components are in good working order. Preventative maintenance can help prevent breakdowns on the road.

What are the benefits of using aftermarket engine cooling parts and components for on-highway commercial vehicle fleets?

Using aftermarket engine cooling parts and components for on-highway commercial vehicle fleets can offer several benefits.

1. Cost savings: Aftermarket parts are often cheaper than OEM parts, allowing fleet operators to save money on maintenance and repairs.

2. Increased availability: Aftermarket parts are more readily available compared to OEM parts, reducing downtime for commercial vehicles.

3. Quality options: Aftermarket parts come in a variety of brands and options, allowing fleet operators to choose the best parts for their specific needs.

4. Improved performance: Aftermarket cooling parts and components may offer better performance compared to OEM parts, leading to more efficient cooling of the engine.

5. Customization: Aftermarket parts often allow for more customization and options, allowing fleet operators to tailor their cooling systems to their specific requirements.

Overall, using aftermarket engine cooling parts and components can help commercial vehicle fleets save money, reduce downtime, and improve the performance of their vehicles.

What are some customized solutions for engine cooling systems in zero-emission vehicles?

Although the knowledge of manufacturing, maintenance, and engine cooling systems in zero-emission vehicles (ZEV) is still growing, there are everal innovative approaches are being explored to address this need:

- Active Thermal Management: Utilizing advanced algorithms and sensors, active thermal management systems can dynamically adjust coolant flow and fan speed based on real-time temperature data. This ensures precise cooling tailored to the vehicle’s operating conditions, maximizing efficiency and battery life.

- Liquid Cooling Systems: In contrast to traditional air-cooled systems, liquid cooling solutions can efficiently dissipate heat from critical components such as electric motors, power electronics, and battery packs. Custom-designed coolant circuits with optimized flow paths can enhance heat transfer efficiency and minimize energy consumption.

- Integrated Heat Exchangers: Integrating heat exchangers into the vehicle’s chassis or body panels can provide additional cooling capacity without compromising aerodynamics or interior space. These innovative designs leverage the vehicle’s structure as a heat sink, enhancing thermal performance while reducing weight and complexity.

- Thermal Insulation and Management: Effective thermal insulation materials and techniques can minimize heat transfer from the powertrain to the passenger compartment, improving cabin comfort and reducing the load on the cooling system. Advanced insulation materials such as aerogels or vacuum-insulated panels offer excellent thermal resistance while being lightweight and compact.

- Variable Geometry Cooling Ducts: Employing adjustable cooling ducts or louvers allows for precise control over airflow distribution, optimizing cooling efficiency for different driving conditions. This adaptive approach ensures effective heat dissipation while minimizing aerodynamic drag and energy consumption.

- Regenerative Cooling Systems: Integrating regenerative cooling technology allows waste heat from the powertrain to be captured and recycled to supplement the cooling system. By harnessing this otherwise wasted energy, regenerative cooling systems can improve overall vehicle efficiency and reduce environmental impact.

- Predictive Maintenance Systems: Implementing predictive maintenance algorithms can proactively identify potential cooling system issues before they escalate, enabling timely intervention and preventing costly repairs or downtime. Real-time monitoring of coolant flow, temperature, and pressure parameters can help optimize system performance and reliability.

By integrating these customized solutions, zero-emission vehicles can achieve optimal thermal management, maximizing efficiency, performance, and reliability while minimizing environmental impact.

Are there any specific challenges in implementing customized solutions for engine cooling systems in zero-emission vehicles?

Implementing customized solutions for engine cooling systems in zero-emission vehicles faces several challenges:

- Efficiency Optimization: Ensuring cooling system efficiency while minimizing energy consumption is crucial for maximizing vehicle range.

- Component Integration: Integrating cooling components into the vehicle’s design without compromising other systems or aesthetics requires careful engineering.

- Thermal Management: Managing heat dissipation from electric powertrains and battery packs without affecting performance or safety is a complex task.

- Cost Considerations: Developing and implementing customized solutions can be expensive, necessitating cost-effective approaches without sacrificing performance.

- Regulatory Compliance: Meeting stringent environmental regulations and safety standards adds complexity to the design and implementation process.

Addressing these challenges requires collaboration between engineers, designers, and manufacturers to develop innovative solutions that balance efficiency, performance, and cost-effectiveness in zero-emission vehicles.